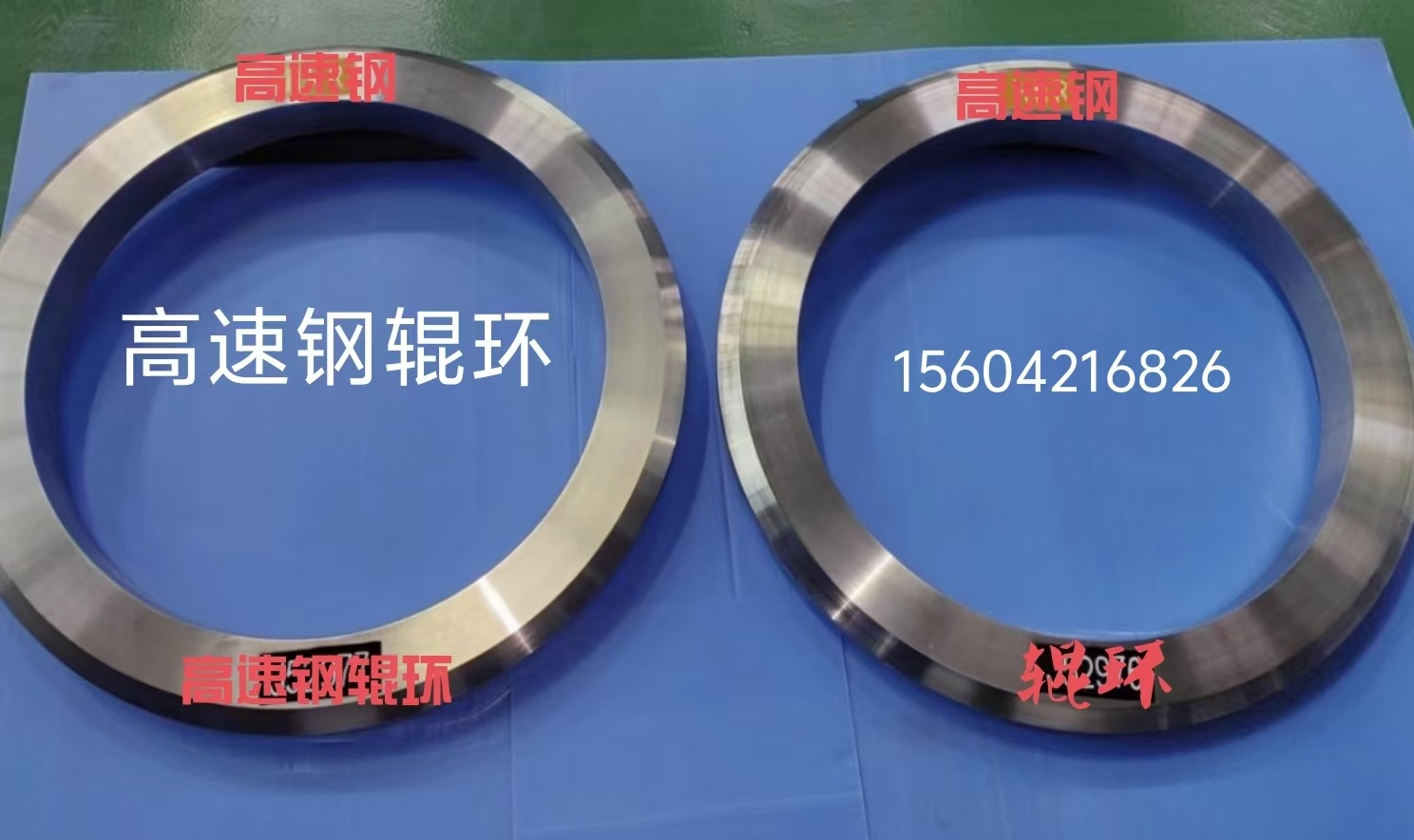

High speed steel roll ring

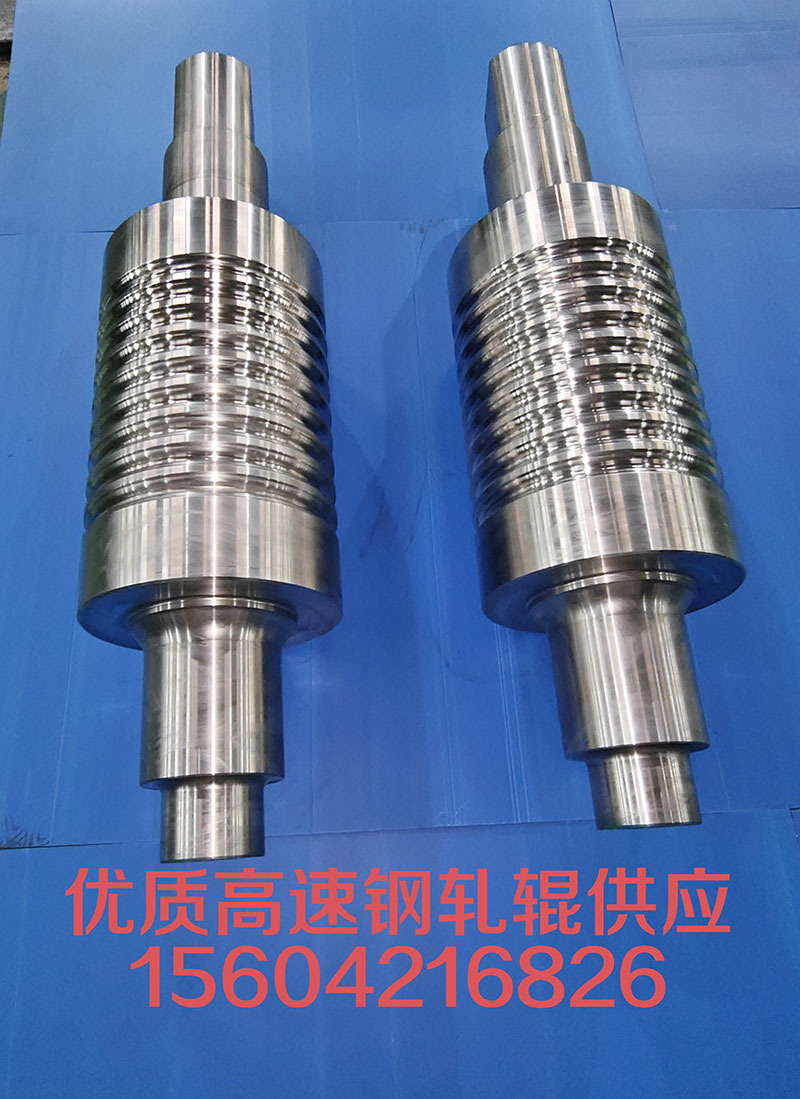

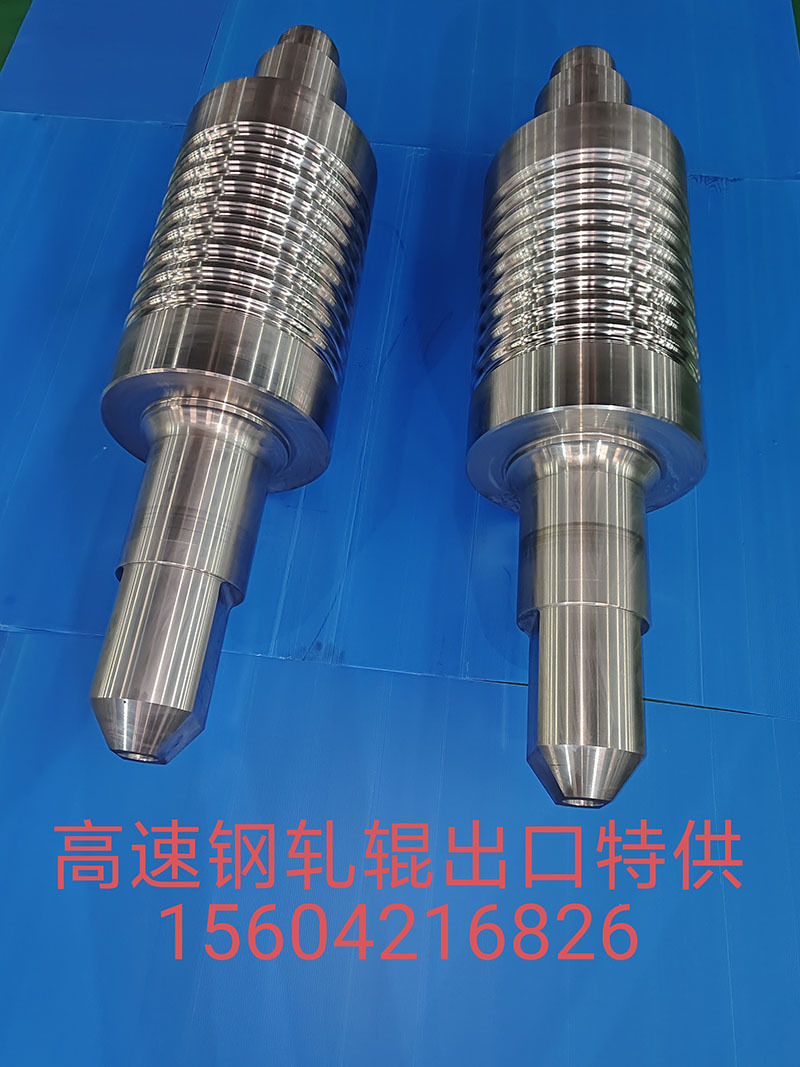

New type of composite high-speed...

Key words:

High speed steel roll ring

Classification:

Hotline:

High speed steel roll ring

| Roll material | Roll body hardness HSD |

roll neck hardness HSD |

Roll neck strength MPa |

Features | Scope of application |

| High Speed Steel Roll I | 60-75 | 35-45 | ≥ 500 | High strength, good heat resistance, good surface roughness | Roughing mill stand for rod and wire mill |

| High Speed Steel Roll II | 70-85 | 35-45 | ≥ 450 | Moderate heat resistance, good wear resistance | For middle rolling stand of bar and wire rod mill |

| High Speed Steel Roll III | 75-90 | 35-45 | ≥ 400 | High hardness, high wear resistance | Normal temperature rolling production line for finishing rolling stand of bar mill |

| YLS high alloy high speed steel roll IV | 80-95 | 35-45 | ≥ 450 | High hardness, good wear resistance, high amount of steel | Controlled rolling and controlled cooling low temperature rolling production line For finishing stand of bar mill |

| YLS high toughness high speed steel roll V | 70-85 | 35-45 | ≥ 400 | Good toughness, high stability | For cutting stand of bar mill |

| YLS Heat Resistant High Speed Steel Roll VI | 60-75 | 35-45 | ≥ 500 | High strength, thermal crack resistance, good fatigue resistance | For roughing stand of endless rolling bar and wire rod mill |

| High Speed Steel Roll VII | 80-95 | 35-45 | ≥ 400 | High hardness, high wear resistance | For finishing rolling stand of strip steel, flat steel and round steel |

| High Speed Steel Roll VIII | 70-85 | 35-45 | ≥ 400 | Good toughness, high stability | For finishing stands of small and angle steel mills |

| High Speed Steel Roll Ring I | 75-90 | 35-45 | ≥ 400 | High hardness, good wear resistance and fracture resistance | For pre-finishing stand of high-speed wire rod mill, vertical roll of strip mill |

| High Speed Steel Roll Ring II | 80-95 | 35-45 | ≥ 400 | High hardness, high wear resistance | Alloy round steel mill for reducing and sizing rack |

| semi-high speed steel roll | 70-85 | 35-45 | ≥ 450 | roller wear resistance is better | For related stands of strip, section, bar and wire mills |

| High chromium cast iron roll I | 70-80 | 35-45 | ≥ 400 | roller wear resistance is better | Strip mill for vertical mill stand |

| High Chromium Cast Iron Roll II | 75-85 | 35-45 | ≥ 400 | roll stability is good | Work roll for finishing rolling of strip mill |

| high chromium cast steel roll | 70-80 | 35-45 | ≥ 400 | roll stability is good | Strip mill for vertical mill stand |

| bainite ductile iron roll | 70-80 | 35-45 | ≥ 400 | roll stability is good | For middle rolling stand of rod and wire mill |

| pearlite ductile iron roll | 60-70 | 35-45 | ≥ 450 | roll stability is good | Rough and medium rolling stands for rod and wire mills, for medium and finishing stands for small mills. |

| Infinite Chilled Cast Iron Roll | 75-85 | 35-45 | ≥ 400 | roll stability is good | Work roll for finishing rolling of strip mill |

| alloy semi-steel roll | 55-65 | 35-45 | ≥ 450 | good anti-spalling performance | Rough and medium rolling stands of rod and wire mill, finish rolling backup rolls of narrow strip mill |

Previous Page

Next Page

Previous Page

None

Next Page

Related Products

Consulting

Filling in your phone/E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.