Finished frame high speed steel roll

New type of composite high-speed...

Key words:

Finished frame high speed steel roll

Classification:

Hotline:

Finished frame high speed steel roll

1. technical advantages

Liaoning Yilian Sheng New Material Co., Ltd. is a professional manufacturer of R & D and production of high-speed steel rolls in China. Its predecessor was Tangshan Yilian Sheng Roll Co., Ltd., which was awarded the "Casting High-speed Steel Roll Production Base" by China Foundry Association and the "Special, Special and New" Advantage Enterprise, is a high-tech enterprise with a municipal high-speed steel roll engineering technology research center, its technical force has the long-term and comprehensive technical support of the high-speed steel roll research and development expert group of China Steel Research Technology Group Co., Ltd.

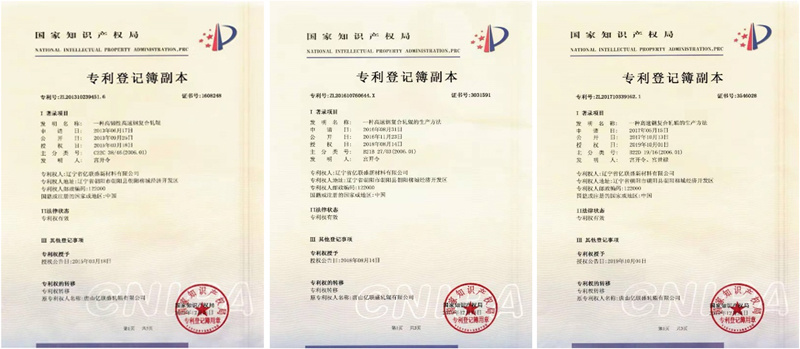

The high-speed steel roll research and development team headed by senior engineer Miyagi is the first high-speed steel roll developer and producer in my country, and also the inventor of the first high-speed steel roll patent in my country. Over the years, he has accumulated rich experience, especially in the development, manufacturing and use of high-speed steel rolls, and has obtained 9 national invention patents, of which 7 belong to high-speed steel roll manufacturing technology. In 2018, he was responsible for drafting and formulating my country's first "Casting High-speed Steel Rolls" (T/CFA 02010116.1-2019) group standard, and successively organized and presided over the first and 2. three national high-speed steel rolls for rod and wire rolling mills. Technical seminars. It is also one of the main drafters of China's current national roll standards GB/T1504-2008 Cast Iron Roll and GB/T25825-2010 Hot Rolled Steel Strip Roll. It has published more than 40 articles and won more than 8 provincial and ministerial level scientific and technological progress awards.

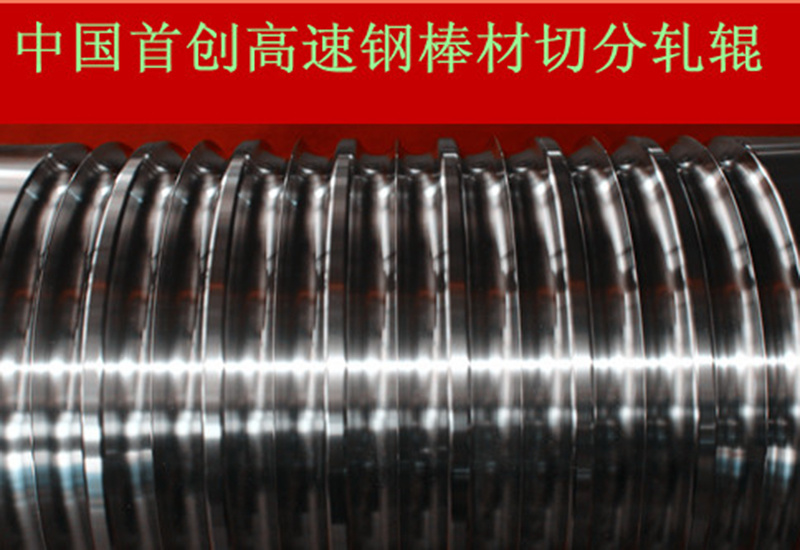

2. the development and production of high-speed steel rolls in series.

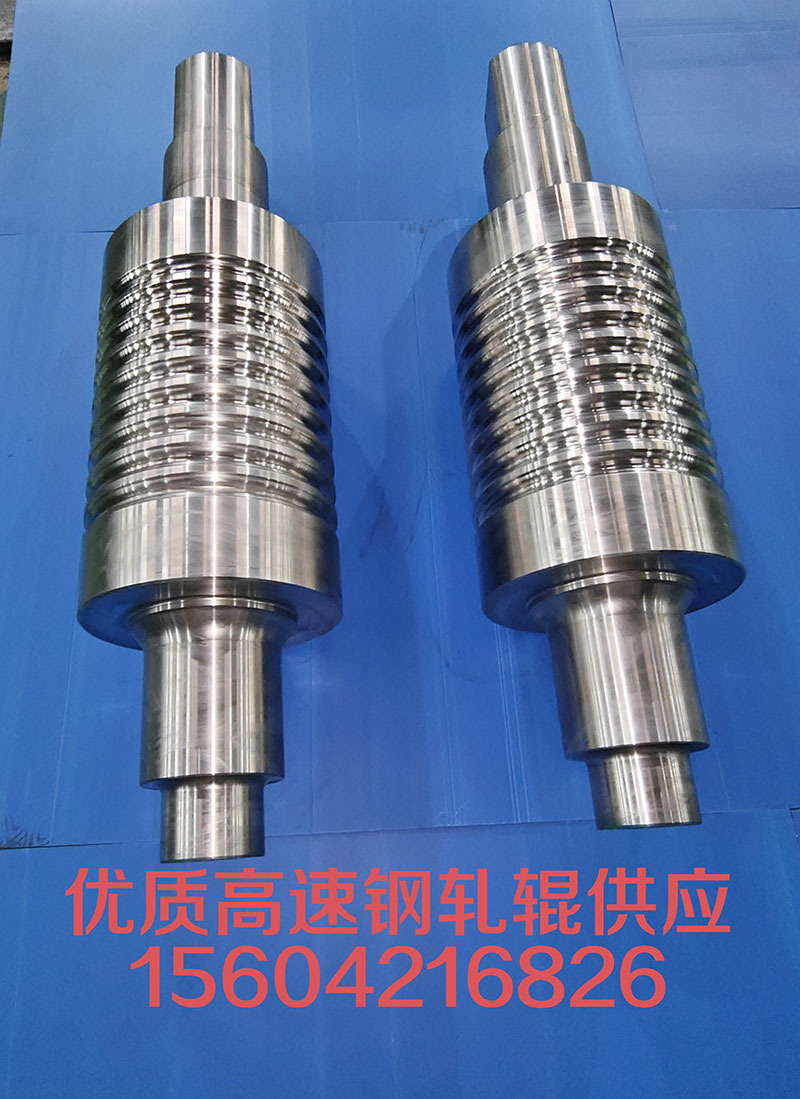

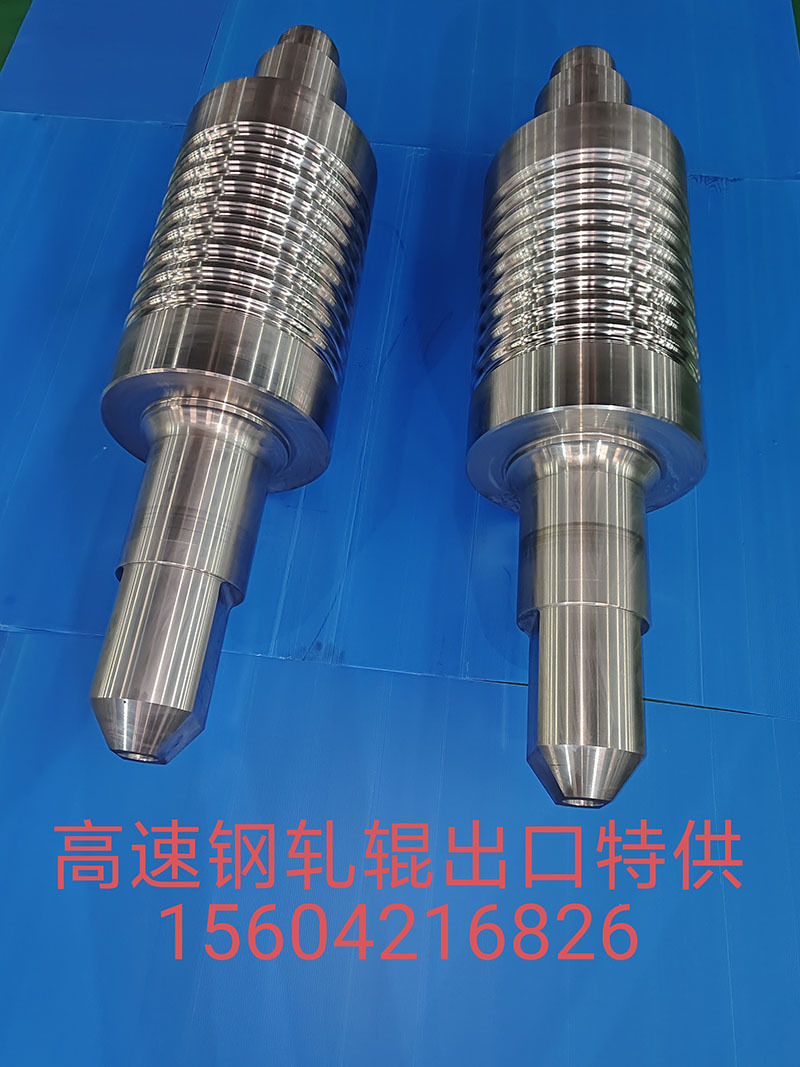

The high-speed steel rolls produced by Yilian Sheng Company are first manufactured in series according to the characteristics of the rolled material and the number of passes and rolling characteristics of the rolling mill. For example, the high-speed steel rolls used in the production of the finished frame of the bar mill, the high-toughness high-speed steel rolls used in the cutting frame, the high-speed steel rolls used in the middle rolling stand, the heat-resistant cracking high-speed steel rolls used in the roughing mill, and the high-controlled cold control rolling production line, recently, Yilian Sheng Company is developing a new generation of high-strength, heat-resistant and high-wear-resistant high-speed steel rolls used in the endless rolling production line of bar continuous rolling mills. The second is to optimize the composition of high-speed steel rolls and avoid the problem of segregation in centrifugal production. At the same time, the heat treatment process of high-speed steel rolls is improved to enhance the uniformity of roll hardness. The high-speed steel roll produced by the company, through the optimization of composition and the improvement of heat treatment process, the surface hardness uniformity of the roll body is not more than 2HSD, and the cutting performance of the roll is significantly improved. The hardness drop of the working layer is not more than 1HSD, the stability of the roll is greatly increased, and the comprehensive service life of the roll can be increased by about 20% compared with similar products in the past, but the sales price of the roll is not increased.

3. product classification

High-speed steel rolls on the finished frame for rolling threaded steel

The high-speed steel roll used in the finished rolling frame of threaded steel should not only consider the wear resistance of the roll, but also consider the toughness of the roll, and at the same time take into account the difficulty of the cross rib milling process. The performance of the roll is good or bad, depending on the final roll of the organizational state, casting high-speed steel is different from forging high-speed steel, the form of carbide can not be changed by deformation, only by adjusting the chemical composition, solidification conditions and heat treatment process to obtain, in order to achieve the requirements of the roll performance. Obtaining high hardness granular carbide and fine matrix structure is the basic guarantee to improve roll performance. According to the different operating conditions of each rolling line, the hardness of the working layer of the roll is controlled at 82-86HSD, and the hardness uniformity of the roll surface of the same roll is not more than 2 HSD, which greatly improves the wear resistance of the roll and the uniformity of cutting processing. Due to the good hardenability of the high-speed steel roll, the hardness drop from the surface of the roll body to the inside of the working layer is less than 1HSD, so, so as to ensure the stability of the use of high-speed steel roll. At the same time, the surface quality of rolled materials can be significantly improved, which enhances the market competitiveness of products. Moreover, the service life of rolls is long, the number of roll changes is small, the operation rate of rolling mills and the daily output are also greatly improved, usually the daily output can be increased by 10-20%, which reduces the cost per ton of rolling costs, reduces the consumption of rolls and the waste of resources, especially the improvement of the dimensional accuracy stability of rolled materials is more effective, the control rate of negative difference stability can be increased by 1-2%, which increases the efficiency of the enterprise.

4. science and technology innovation

5. product specifications

| Roll material | Roll body hardness HSD |

roll neck hardness HSD |

Roll neck strength MPa |

Features | Scope of application |

| High Speed Steel Roll I | 60-75 | 35-45 | ≥ 500 | High strength, good heat resistance, good surface roughness | Roughing mill stand for rod and wire mill |

| High Speed Steel Roll II | 70-85 | 35-45 | ≥ 450 | Moderate heat resistance, good wear resistance | For middle rolling stand of bar and wire rod mill |

| High Speed Steel Roll III | 75-90 | 35-45 | ≥ 400 | High hardness, high wear resistance | Normal temperature rolling production line for finishing rolling stand of bar mill |

| YLS high alloy high speed steel roll IV | 80-95 | 35-45 | ≥ 450 | High hardness, good wear resistance, high amount of steel | Controlled rolling and controlled cooling low temperature rolling production line For finishing stand of bar mill |

| YLS high toughness high speed steel roll V | 70-85 | 35-45 | ≥ 400 | Good toughness, high stability | For cutting stand of bar mill |

| YLS Heat Resistant High Speed Steel Roll VI | 60-75 | 35-45 | ≥ 500 | High strength, thermal crack resistance, good fatigue resistance | For roughing stand of endless rolling bar and wire rod mill |

| High Speed Steel Roll VII | 80-95 | 35-45 | ≥ 400 | High hardness, high wear resistance | For finishing rolling stand of strip steel, flat steel and round steel |

| High Speed Steel Roll VIII | 70-85 | 35-45 | ≥ 400 | Good toughness, high stability | For finishing stands of small and angle steel mills |

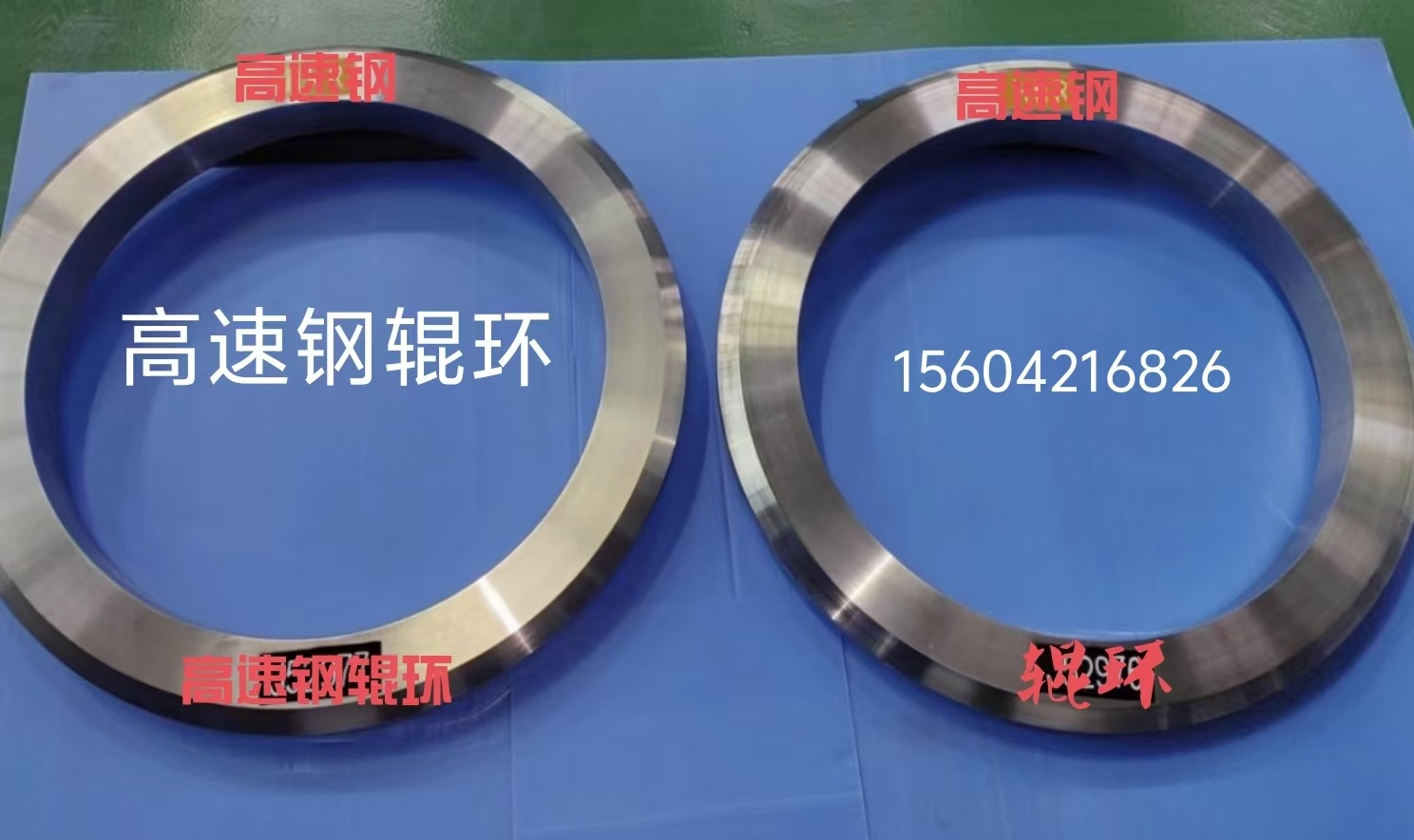

| High Speed Steel Roll Ring I | 75-90 | 35-45 | ≥ 400 | High hardness, good wear resistance and fracture resistance | For pre-finishing stand of high-speed wire rod mill, vertical roll of strip mill |

| High Speed Steel Roll Ring II | 80-95 | 35-45 | ≥ 400 | High hardness, high wear resistance | Alloy round steel mill for reducing and sizing rack |

| semi-high speed steel roll | 70-85 | 35-45 | ≥ 450 | roller wear resistance is better | For related stands of strip, section, bar and wire mills |

| High chromium cast iron roll I | 70-80 | 35-45 | ≥ 400 | roller wear resistance is better | Strip mill for vertical mill stand |

| High Chromium Cast Iron Roll II | 75-85 | 35-45 | ≥ 400 | roll stability is good | Work roll for finishing rolling of strip mill |

| high chromium cast steel roll | 70-80 | 35-45 | ≥ 400 | roll stability is good | Strip mill for vertical mill stand |

| bainite ductile iron roll | 70-80 | 35-45 | ≥ 400 | roll stability is good | For middle rolling stand of rod and wire mill |

| pearlite ductile iron roll | 60-70 | 35-45 | ≥ 450 | roll stability is good | Rough and medium rolling stands for rod and wire mills, for medium and finishing stands for small mills. |

| Infinite Chilled Cast Iron Roll | 75-85 | 35-45 | ≥ 400 | roll stability is good | Work roll for finishing rolling of strip mill |

| alloy semi-steel roll | 55-65 | 35-45 | ≥ 450 | good anti-spalling performance | Rough and medium rolling stands of rod and wire mill, finish rolling backup rolls of narrow strip mill |

Previous Page

Next Page

Previous Page

High speed steel roll to be launched

Next Page

Related Products

Consulting

Filling in your phone/E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.