09

2022

-

05

What should I do if a roll breaks?

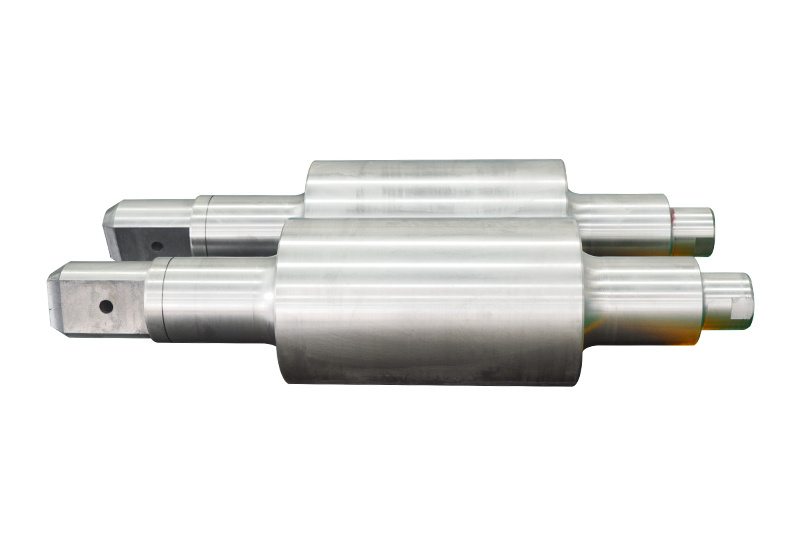

If Roll What to do if it breaks? Finding the cause of roll breakage is easy to solve.

In practical applications, roll breakage is common. So, do you know the specific reasons for roll breakage? Today, I will give you a detailed introduction.

1. When the rolling temperature is low, the rolling pressure increases, and the rolling force is greater than the critical strength of the roll, breakage will occur.

2. Insufficient water to meet the roller body, leading to stress concentration and breakage.

3. Improper roller selection. The selection of rolls for 850 rolling mills should prioritize toughness, with hardness and wear resistance as secondary considerations. For example, cast iron rollers are prone to breakage.

4. Tough fracture. The fracture shape of this type of roll is mostly "mushroom head", and the roller body near the fracture is crushed.

5. Whether the motor speed is too high. Generally Roll There is a process of eliminating pre-stress, which is often overlooked. It should be considered that sometimes rolls that do not roll steel will jam themselves.

6. Unpacking too early, excessive stress, leading to breakage.

7. The cold mold is too thin, the cooling speed is too fast, leading to stress fracture.

8. Centrifuge vibration, insufficient smoothness of the cold track, leading to outer layer fragmentation.

9. Severe cracks on the surface of the cold mold lead to hindered shrinkage, and tensile stress causes cracks in the roll.

The roll bearings of the rolling mill are an important component of the rolling mill. Their characteristics are high unit pressure and a large range of operating speed changes, making the bearing temperature unstable. Therefore, the bearings are required to have high load-carrying capacity. In the design process of the rolling mill, how to correctly select the roll bearings is a very important task.

The roller bearings used in strip rolling mills mainly include sliding bearings and rolling bearings.

I. Selection of rolling bearings

1. Types of radial bearings

Rolling bearings have advantages such as low friction coefficient, high precision, easy serialization and mass production. Therefore, rolling bearings are mostly used in strip rolling mill rolling bearings.

(1) Compared with double-row self-aligning roller bearings and tapered roller bearings, multi-row cylindrical roller bearings can withstand larger external loads under the same size, and their applicable operating speed is much higher than the former two. However, it cannot withstand axial loads. When using this bearing, a separate thrust bearing is needed to withstand the axial load, so that the multi-row cylindrical roller bearing can fully withstand the radial load.

(2) Four-row tapered roller bearings Because the rollers of four-row tapered roller bearings have an angle with the horizontal plane during installation, they can withstand both radial and axial loads.

(3) Double-row self-aligning roller bearings Double-row self-aligning roller bearings also need to have a certain angle with the horizontal plane during installation, which can withstand both radial loads and smaller axial loads, and has self-aligning characteristics.

That's all Roll of the relevant knowledge points introduced.

Roll

Next Page

Innovation-driven, win-win cooperation

2025-06-17