25

2022

-

05

Below is a brief explanation of roll maintenance and production standards

Let me briefly explain Roll maintenance and production standards

Maintenance and Management of Steel Rolls

1. Correctly judge the number of uses. The grinding interval of high-speed steel rolls depends on the oxide film on the roll surface and the roughness retention after each shutdown. Generally, the front roll stand can be used 3-7 times, and the rear roll stand can be used 2-4 times. High-speed steel rolls can even be used more than 10 times.

2. Avoid roll failure through roll surface flaw detection. After high-speed steel rolls are removed, they should be immediately water-cooled or air-cooled to eliminate thermal expansion before the next use. High-speed steel rolls are prone to thermal cracks. If abnormal shutdown occurs, the high-speed steel rolls should be replaced immediately. To avoid roll peeling and other failure accidents, an ultrasonic flaw detector should be used to detect surface cracks in the cooled rolls.

3. Use professional tools to enhance the grinding effect. Due to the high hardness of high-speed steel rolls and the difficulty of grinding, special grinding wheels and automatic grinding machines should be used. After grinding, use an eddy current flaw detector and an ultrasonic flaw detector for composite flaw detection on the roll surface. After grinding, ordinary machine tool high-speed steel rolls can retain micro-heat cracks for use on the machine tool. However, for high-speed steel rolls that have been tripped in rolling accidents, a certain amount of grinding should be added on the basis of grinding to remove surface cracks.

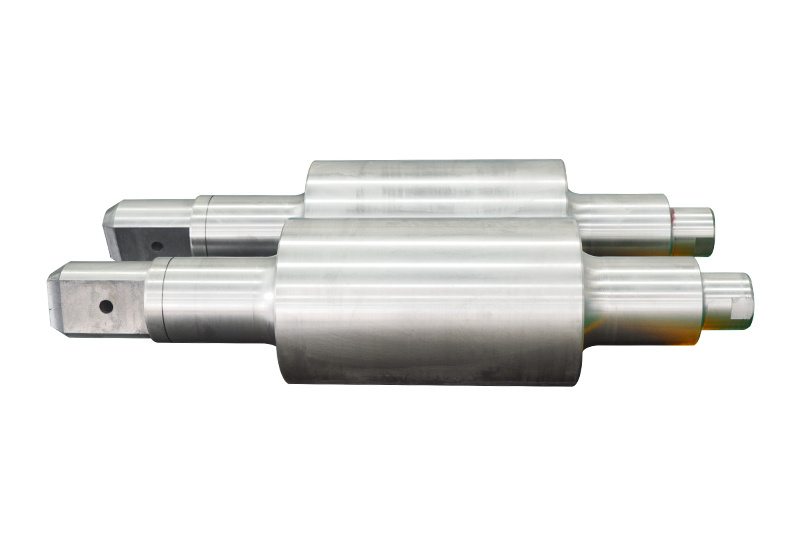

Production Standards for Rolls

Rolls are an important component of rolling mills, using one or a set of Roll pressure to roll and grind steel. It mainly bears the influence of static and dynamic loads, wear, and temperature changes during the rolling process. The produced rolls are made of iron and have professional quality assurance. Because they are professional, they are very good.

Common cold Roll include 9Cr, 9Cr2, 9Crv, 8CrMoV, etc. Cold rolls require surface quenching, with a hardness of HS45-105. Commonly used hot rolling materials include 55Mn2, 55Cr, 60CrMnMo, 60SiMnMo, etc. Hot rolling is used for processing blooms, thick plates, and shaped steel, bearing large rolling forces, severe wear, and thermal fatigue. The working temperature of hot rolls is high, and the allowable diameter wear within the unit workload is high, so surface hardness is not required, only high strength, toughness, and heat resistance are required.

Hot rolls only use overall normalizing or quenching, with a surface hardness requirement of HB190-270. Roll hardness is an indirect physical quantity, and its level is affected by the internal organizational state of the roll itself, such as the matrix hardness of the roll material, the type and quantity of carbides in the roll material, and the residual stress of the roll. At the same time, because the commonly used Shore hardness test and Rockwell hardness test in roller hardness tests are rebound hardness tests, they are greatly affected by other factors such as the state of the testing instrument and the psychological factors of the operator.

Therefore, both the manufacturing and use departments of rolls should designate a dedicated person to be responsible for hardness testing, pay attention to the selection of hardness testers, maintain a stable comparison with other hardnesses, pay attention to the regular inspection and calibration of hardness testing instruments and standard test pieces, and enterprises with conditions can promote the use of standard rolls for hardness tester calibration.

I have explained this to everyone. Thank you for watching. If you need Roll production, you can contact our company.

Roll

Previous Page

Next Page

Previous Page

Next Page

Innovation-driven, win-win cooperation

2025-06-17