08

2022

-

06

Understanding Roll Materials and Common Issues

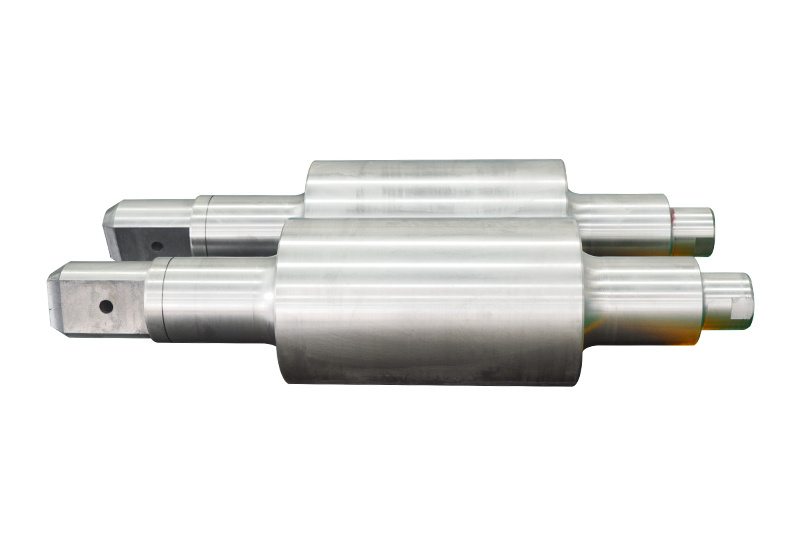

Roll Rolls are tools used for plastic deformation of (rolled) metals. They are important wearing parts that determine the efficiency of rolling mills and the quality of rolled materials. Rolls are an important component of rolling mills in steel plants, using the pressure generated by a pair or a set of rolls to roll steel. They are mainly affected by dynamic and static loads, wear, and temperature changes during the rolling process. So, what are the characteristics and common problems of rolls? Let's take a look below.

I. Classification and Material of Rolls

1. Classification: There are usually two types of rolls used, namely cold rolling rolls and hot rolling rolls.

2. There are many types of materials made by cold rolling, such as 9Cr and 9Cr2. This type of roll has two requirements: first, the surface of the roll needs to be quenched; second, its surface hardness needs to be between HS45 and 105.

The material of hot rolling rolls is generally 60CrMnMo, 55Mn2, etc. This type of roll can be used in a wide range of fields, such as steel profiles, bars, rebar, high-speed wire rods, seamless steel pipes, steel billet cutting, etc. It withstands strong rolling forces, severe wear and thermal fatigue. Moreover, the working temperature of hot rolling rolls is high, and the diameter wear allowed per unit of work is allowed, so surface hardness is not required, only high strength, toughness and heat resistance are required. Hot rolls only use overall normalizing or quenching, and the surface hardness is required to be HB190~270 hardness.

II. Common Roll Failure Modes and Causes

1. Cracks. Cracks are mainly caused by excessive local pressure and rapid cooling and heating of the rolls. On the rolling mill, if the emulsion nozzle is blocked, resulting in poor local cooling conditions of the rolls, cracks will occur. Because the temperature is low in winter, it is easier to crack than in summer.

2. Scaling. If the cracks continue to develop, it will form blocky or flaky spalling. Light scaling can be re-ground and reused, while severe scaling is scrapped.

3. Pitting. Pitting is mainly caused by the welding seam or other foreign matter of the strip entering the rolling mill, leaving pits of different shapes on the surface of the roll. Usually, the grooved roll needs to be replaced. When the quality of the strip weld is poor, the rolling operation should be lifted and pressed down when passing through the weld to prevent scratches.

4. Roll sticking. Roll sticking, also known as sticking, is caused by broken pieces, wavy folds, and broken edges during cold rolling. Under high pressure and instantaneous high temperature, it is easy to form bonding between the steel strip and the roll, causing small-area damage to the roll. After grinding to eliminate surface cracks, the roller can still be used, but the service life is significantly reduced, and scaling accidents are prone to occur in later use.

5. Roll pinching. It is mainly caused by excessive reduction, resulting in heavy or slight folding of the strip and strip deviation, resulting in heavy skin. When the roll is severely pinched, the roll will be stuck, and the strip will crack. When the roll pinching is slight, there are pinch marks on both the strip and the roll.

6. Fracture. The main causes of roll fracture are overpressure (i.e., excessive rolling pressure), Roll internal defects and stress fields caused by uneven roll temperature.

Roll

Previous Page

Innovation-driven, win-win cooperation

2025-06-17